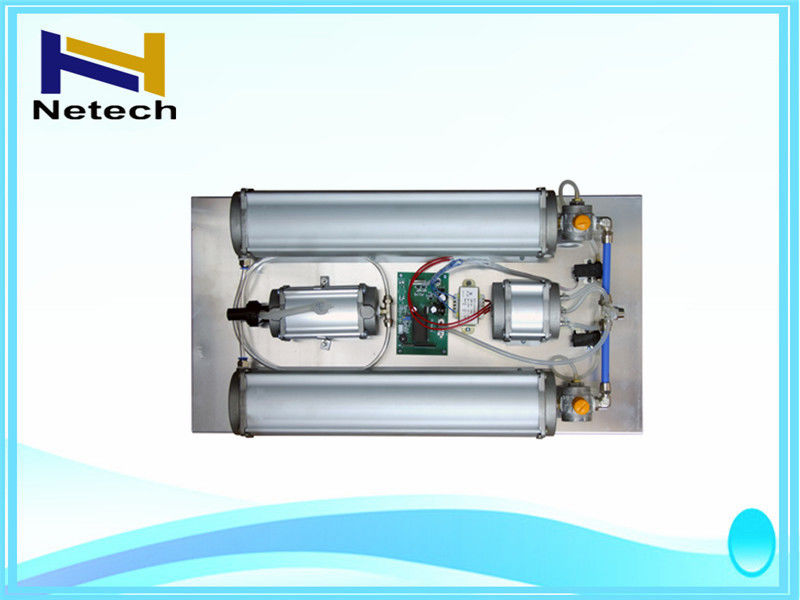

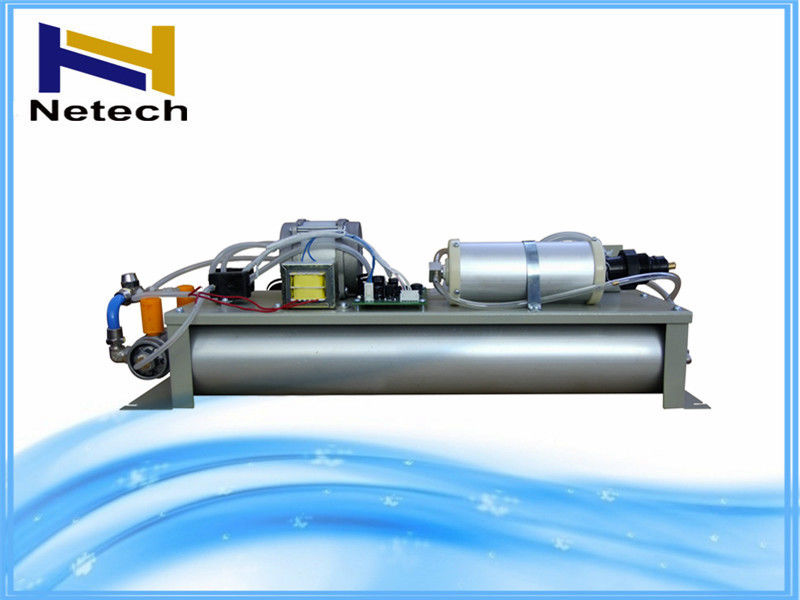

Zeolite Two Tower Portable Oxygen Concentrator Parts 220V 110V 3LPM 5LPM 10LPM 15LPM

-

High Light

molecular sieve unit

,oxygen molecular sieve

-

Concentration95%

-

Noise≤ 60Db

-

Outlet Pressure0.06~0.08Mpa

-

Oxygen Purity3% + - 3%

-

Warranty1 Year

-

Place of OriginGuangdong China

-

Brand NameNetech

-

Model NumberNT-OX

-

Minimum Order Quantity1 set

-

PriceFor futher discussion

-

Packaging DetailsSafe double carton package with foam inside for protection

-

Delivery Time5-10 days after payment confirmed

-

Payment TermsL/C D/A D/P T/T Western Union Credit Card/ Paypal

-

Supply Ability1000 sets per month

Zeolite Two Tower Portable Oxygen Concentrator Parts 220V 110V 3LPM 5LPM 10LPM 15LPM

220V 110V 3LPM 5LPM 10LPM 15LPM Zeolite Two Tower Oxygen Concentration Parts

Drinking water is treated to kill or inactivate any pathogenic micro-organisms such as viruses, bacteria and parasites, to remove inorganic and organic trace contaminants which have found their way into the water system because of pollution and to reduce the naturally occurring organic compounds such as humic acid and algal metabolites. In general, surface waters such as lakes and rivers contain higher levels of micro-organisms and are more prone to contamination than groundwater and require different treatment regimes. To reduce the risk to consumers, more and more countries are introducing new drinking water regulations containing stricter limits on pathogens and contaminants.

Quick Detail

oxygen generator concentrator

1. About 95% concentration

2. Stable oxygen output

3. Each tower working independently

4. Durable

Appliance of oxygen machine:

• Welding / Brazing Furnace Enrichment

• Fermentation Glass Industry

• Fish Farming Ozone Generator

• Sewage Treatment Pulp & Paper

• Chemical Oxidation Rough Cutting

• Battery Manufacture Melting

• Mini-Steel Mills Cement & Lime Kilns

• Metal Spraying Copper Smelting

Sheet:

| Item | Unit | NTOX3AL | NTOX5AL | NTOX7AL | NTOX10AL | NTOX15AL |

| Oxygen output | LPM | 3 | 5 | 7.5 | 10 | 15 |

| Oxygen concentration | % | 90%±3% | 90%±3% | 90%±3% | 90%±3% | 90%±3% |

| Air flow rate | LPM | 36-45 | 60-75 | 90-115 | 90-115 | 180-200 |

| Pressure(inlet) | Mpa | 0.14-0.18 | 0.14-0.2 | 0.15-0.21 | 0.18-0.25 | 0.35 |

| Pressure(outlet) | Mpa | 0.06-0.08 | 0.06-0.08 | 0.06-0.08 | 0.06-0.08 | 0.06-0.08 |

| Temperature | ℃ | indoor temperature | ||||

| Relative humidity | % | ≤ 70%±10% | ||||

| Noise | Db | ≤ 60 | ≤ 60 | ≤ 60 | ≤ 60 | ≤ 60 |

| Dimension | mm | Ф200 * 310 | Ф200 * 430 | Ф200 * 500 | Ф200 * 560 | Ф200 * 880 |

| Net weight | kg | 15.70 | 18.30 | 19.30 | 30.60 | 32.5 |

Instruction

12 Towers Oxygen Concentrator

1. ed products NT-OT series molecular sieve is an air separation plant which has already obtained domestic .

2. Rational construction Modular construction is the main points of our molecular sieve. Through the different combination of oxygen units, the oxygen output can be from 1 LPM to 160 LPM, even higher.

3. Easy to control Each unit can be work independently, according to the different oxygen output requirement. And free control for the different unit combinations. So that, it can be suitable used for the standardization of products. Meanwhile, maintenance will be more convenient.

4. The oxygen output is stable and continuously

5. Low-pressure oxygen production working pressure less than 3 KG.

Specifications

Quality control

Every procedure has personnel inspection.

All the products must be tested and qualified before packaging.

After sales service

We provide 12 month free maintenance.

The buyer should return the product in the original conditions to us and should

bear the shipping costs for return.

![]()

![]()

![]()